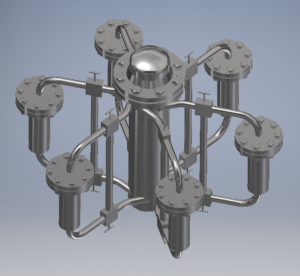

Reactor design is in full swing.

After collecting the habitat parameters of the target organisms it has become obvious that we will not get far with standard steels; would have been too easy anyway. Standard parts made from the necessary material are in short supply, however. At the same time data sheets and dimensions of peripherals and reactor probes are constantly trickling in.

Overall, this results in a highly fluctuating planning situation. A variable 3D sketch should give a framework to the reactor design. Once the available components have been inquired and listed by the usual suppliers, the variable 3D model can be used to generate various possible reactor variants. It remains to be seen which will win the race in the end. Justifiers here are: The quality of flow control, other pending data, and last but not least, the German Technical Inspection Association (TÜV), which has a say in safety factors.